In order to minimize pesticide exposure, pesticide labels prescribe proper personal protective equipment (PPE) along with other safety measures. Wearing the proper PPE when working with pesticides reduces the chance of dermal, inhalation, ocular and oral exposure, thus lowering the chances of pesticide related injury, illness and poisoning. According to the Environmental Protection Agency (EPA), personal protective equipment includes coveralls, aprons, gloves, footwear, headgear, eyewear and respirators. PPE standards are set to reduce exposure to pesticides, not eliminate it. In this packet, we will give examples of proper PPE along with good work practices that will help protect you from pesticide poisoning.

Preventing Pesticide Exposure

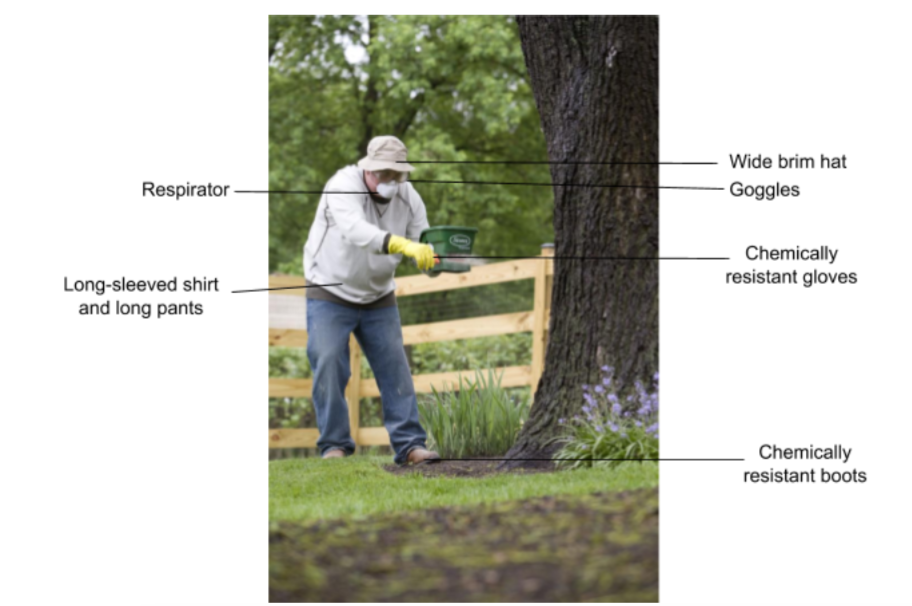

PPE requirements are listed under the “Precautionary Statements” or, if you work in a farm or

greenhouse setting, “Agricultural Use Requirements” section of the pesticide label. It is also

important to check your state regulations, as some may have more strict requirements than the

federal pesticide laws. All pesticide handlers (applicators, mixers, loaders and flaggers) must

wear the minimum PPE listed on the label. Wearing anything less than required is not only

dangerous, it is illegal. An example of standard PPE is shown below.

In addition to appropriate PPE, it is important to take these basic steps to reduce your exposure when handling pesticides.

- ● To prevent oral exposure, never eat, drink, chew gum, use tobacco products or handle cell phones while working with pesticides.

- ● To prevent dermal exposure, wash your hands before using the bathroom and be careful not to wipe contaminated gloves onto clothing – the pesticide may seep through to your skin.

- ● To prevent ocular exposure, wear protective eyewear to protect against accidental splashes or product drifts.

- ● To prevent inhalation exposure, wear a respirator to avoid breathing in a pesticide. It is a good idea to wear a respirator even when it is not required by the label.

-

● Aside from just wearing PPE, you must also take care of it. Wash gloves with soap and

water, launder your work clothes separately and take a shower after handling pesticides.

PPE Breakdown

When it comes to PPE, all clothing, gloves, boots and hats are not created equal. In this section, we will breakdown each standard piece of PPE. Everyday Work Clothing p rovides a basic barrier between the pesticide handler and the pesticide. At a minimum, you should always wear a long-sleeved shirt, long pants, closed-toe shoes and socks when handling pesticides. Your work clothes should be free of any holes or tears and should be laundered separately. Remember, it is important to wear all PPE even during hot summer months. This can restrict your sweat from evaporating, causing heat-related illnesses. Know the symptoms of heat stroke before working on hot days. Some pesticide labels require you wear coveralls over your work clothes. This protective second layer of clothing must be loose-fitting and cover the entire body (except for head, hands and feet). The coveralls may be reusable or disposable, however, disposable is usually recommended because it cuts down on decontamination time and lowers your risk of exposure. No matter the material, make sure your coveralls do not rip, tear and puncture easily. When mixing or loading a pesticide or cleaning application equipment, the label may require you to wear an apron. The apron should cover the front of your body, from your chest to your knees. Headgear may be required during overhead applications to protect your head, neck and back from pesticide sprays. Whether you are using a wide brim hat or a hood, the headgear must be water resistant. Avoid headgear made of cotton, straw or leather. As mentioned with work clothing, closed-toe shoes and socks are always required when applying pesticides. The pesticide label will indicate if you need more protective footwear while on the job. For example, some labels require chemical-resistant footwear, which is defined by the EPA as preventing any measurable amount of material from moving through the fabric or

material of the footwear. In most cases, a heavy-duty pair of unlined rubber boots will provide good protection against pesticides. Options with leather or cloth are not as protective and will soak up any pesticide they come in contact with. Your work boots should only be used on the job to avoid pesticide exposure or contamination and should be washed down at the end of every day.

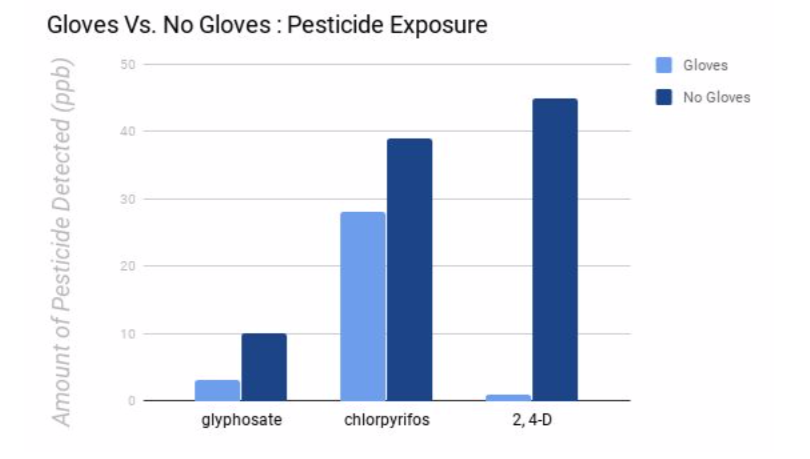

Pesticide handlers experience most exposure from pesticides on their hands and forearms, but wearing protective gloves can cut down the risk of exposure by 99%. The pesticide label may require waterproof gloves or a specific type of glove (e.g., nitrile rubber, neoprene rubber or barrier laminate) that can stand up to the solvents in the product without deteriorating. Never use gloves made of an absorbent material, lining or flocking. Along with the material of your gloves, the size is very important. Gloves that are too big could hinder your dexterity when maintaining or calibrating equipment, while gloves that are too small may rip or tear while in use.

Because of the blood vessels that sit so close to the surface of the eye, pesticides are quickly absorbed through the eye. Protective eyewear, such as goggles, face shields, safety glasses or full face respirators can help prevent ocular exposure in the event of pesticide drift or accidental splashes. Different products require different types of eyewear, read the label to be sure you are protected.

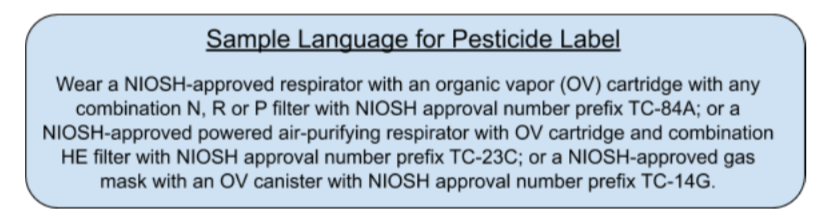

A respirator is a device that protects pesticide handlers from inhaling contaminated air (e.g., toxic gases, vapors or particulates). The label will state whether or not you need a respirator when handling the pesticide, and if so which type. There are two common classes of respirators required for protection from inhalation exposure: atmosphere-supplying and a ir-purifying respirators.

Atmosphere-supplying respirators provide clean, breathable air from an uncontaminated source (e.g., self-contained breathing apparatus).

Air-purifying respirators (ARPs) actively remove specific contaminants from the air that you breathe. Unlike Atmosphere-supplying respirators, ARPs do not supply oxygen from another source and should not be used in spaces where there is limited oxygen. The elements in ARPs that remove particulates are called filters, chemical cartridges or chemical canisters depending on what elements they are blocking.

Particulate filters remove dusts, aerosols and sprays that are suspended in the air. Filters do not help with removing gases or vapors from the air. The EPA requires that you replace these filters according to the respirator manufacturer’s recommendations or the pesticide labeling. You should choose the recommendation that is most frequent. If there are no directions on replacement and use, dispose of the filters after every 8 hour use.

Chemical cartridges and canisters remove contaminant-specific gases and vapors, never particulates! The most common cartridge or canister to appear on labels is an organic vapor (OV) removing cartridge or canister, but always check the label to see what is required. Never use a chemical cartridge or canister after its expiration date, even if the product has never been opened. During use, if you smell or taste anything unusual, stop what you’re doing and change your cartridge or canister immediately. Always dispose of chemical cartridges at the end of a workday.

For full protection before using a respirator, you should consult your doctor to make sure you’re not endangering your health, read the manufacturer’s instructions and conduct a fit test. When wearing a tight-fitting respirator, it is crucial that nothing interferes with the seal of the mask and your skin – including beards and stubble. Fit testing helps you select the correct size and type of respirator for your face. You should perform two tests when determining the correct respirator: quantitative and qualitative.

Qualitative tests use a testing agent outside the mask to test for leakage at the seal to the face. Kits for this type of testing are readily available and easy to use.

Quantitative tests use instrumentation to numerically measure leakage into the respirator. You should perform these tests whenever you experience any physical changes (e.g., facial scarring, dental work or cosmetic surgery) that could affect the fit of your tight-fitting mask.

Pesticide label recommendations for respiratory protection use the National Institute for Occupational Safety and Health (NIOSH) testing and certification (TC) designations. These designations correspond to the types of respirators needed when handling the pesticide. See the chart below for respirator designation descriptions.

| TC-84A |

Filtering facepiece respirators (N, R or P) APR with particulate filters (Nr, R or P) APR with combination chemical cartridge and particulate filter (N, R or P) |

| TC-21C | Powered air-purifying respirator with particulate filter (HE) |

| TC-23C |

APR with chemical cartridges PAPR with chemical cartridges PAPR with combination chemical cartridges and particulate filter (HE) |

| TC-14G |

Gas mask with or without particulate filter (N, R or P) Tight-fitting PAPR with gas canister with or without particulate filter (HE) |

| TC-13F |

Self-contaminated breathing apparatus Supplied-air respirator with a self-contaminated escape bottle |

| TC-19C | Supplied-air respirator |

Maintaining Your PPE

At the end of each workday, you should properly clean or dispose of the PPE you used.

Work clothing and coveralls should be washed separate from other laundry with hot water and

heavy-duty detergent for two full cycles. Before washing household laundry, run an additional

cycle with hot water, detergent and no clothes to wash out the washing machine. If clothing is

heavily contaminated, properly dispose of it as household hazardous waste.

Clean your boots and gloves even if you used them for a brief period of time. Wash your gloves with soap and water before taking them off. Remove your boots and wash the inside and outside thoroughly. Carefully inspect these items to ensure that there are no rips or tears. If you see any signs of wear, dispose of the item.

Most eyewear, respirator bodies and helmets may be worn more than once (and may last years) if properly used and cleaned according to the manufacturer’s directions. Wash eyewear and helmets with soap and water, then dry thoroughly. For respirators, properly dispose of any expendable components, such as filters, cartridges and canisters. Then carefully wash the

facepiece, taking care to clean under and around gaskets and valves. Allow your respirator to air dry and store in a cool, dry place.

Summary

● In order to minimize pesticide exposure, pesticide labels prescribe proper personal protective equipment (PPE) along with other safety measures. Wearing the proper PPE when working with pesticides reduces the chance of dermal, inhalation, ocular and oral exposure, thus lowering the chances of pesticide related injury, illness and poisoning.

● All pesticide handlers (applicators, mixers, loaders and flaggers) must wear the minimum PPE listed on the label. Wearing anything less than required is not only dangerous, it is illegal.

● To prevent oral exposure, never eat, drink, chew gum, use tobacco products or handle cell phones while working with pesticides.

● Everyday Work Clothing p rovides a basic barrier between the pesticide handler and the pesticide. At a minimum, you should always wear a long-sleeved shirt, long pants, closed-toe shoes and socks when handling pesticides. Your work clothes should be free of any holes or tears and should be laundered separately.

● As mentioned with work clothing, closed-toe shoes and socks are always required when applying pesticides. The pesticide label will indicate if you need more protective footwear while on the job. For example, some labels require chemical-resistant footwear, which is defined by the EPA as preventing any measurable amount of material from moving through the fabric or material of the footwear. In most cases, a heavy-duty pair of unlined rubber boots will provide good protection against pesticides. Options with leather or cloth are not as protective and will soak up any pesticide they come in contact with.

● Pesticide handlers experience most exposure from pesticides on their hands and forearms, but wearing protective gloves can cut down the risk of exposure by 99%.

● Air-purifying respirators (ARPs) actively remove specific contaminants from the air that you breathe. Unlike Atmosphere-supplying respirators, ARPs do not supply oxygen from another source and should not be used in spaces where there is limited oxygen. The elements in ARPs that remove particulates are called filters, chemical cartridges or chemical canisters depending on what elements they are blocking.

● When wearing a tight-fitting respirator, it is crucial that nothing interferes with the seal of the mask and your skin – including beards and stubble. Fit testing helps you select the correct size and type of respirator for your face. You should perform two tests when determining the correct respirator: quantitative and qualitative.

● Work clothing and coveralls should be washed separate from other laundry with hot water and heavy-duty detergent for two full cycles. Clean your boots and gloves even if you used them for a brief period of time. Most eyewear, respirator bodies and helmets may be worn more than once (and may last years) when properly cleaned and

maintained. For respirators, properly dispose of any expendable components, such as filters, cartridges and canisters after an eight hour work day.

● It is important to wear all PPE even during hot summer months. This can restrict your sweat from evaporating, causing heat-related illnesses. Know the symptoms of heat stroke before working on hot days.